The CURT Trailer Parts Replacement Guide for Essential Maintainance

So, you need to replace worn-out parts on your trailer? Don't worry, this is common. Whether it's due to wear and tear, damage, or you simply want an upgrade, CURT has the replacement trailer parts you need to maintain your trailer and ensure it's functioning at its best for the road ahead.

From trailer couplers and latches to safety chains and trailer jacks, we've got you covered and have a full, comprehensive offering of replacement parts and accessories for your trailer.

In this guide, we will explain what trailer replacement parts are and also explain what the different parts of a trailer are used for. Follow along below!

Parts of a Trailer Diagram

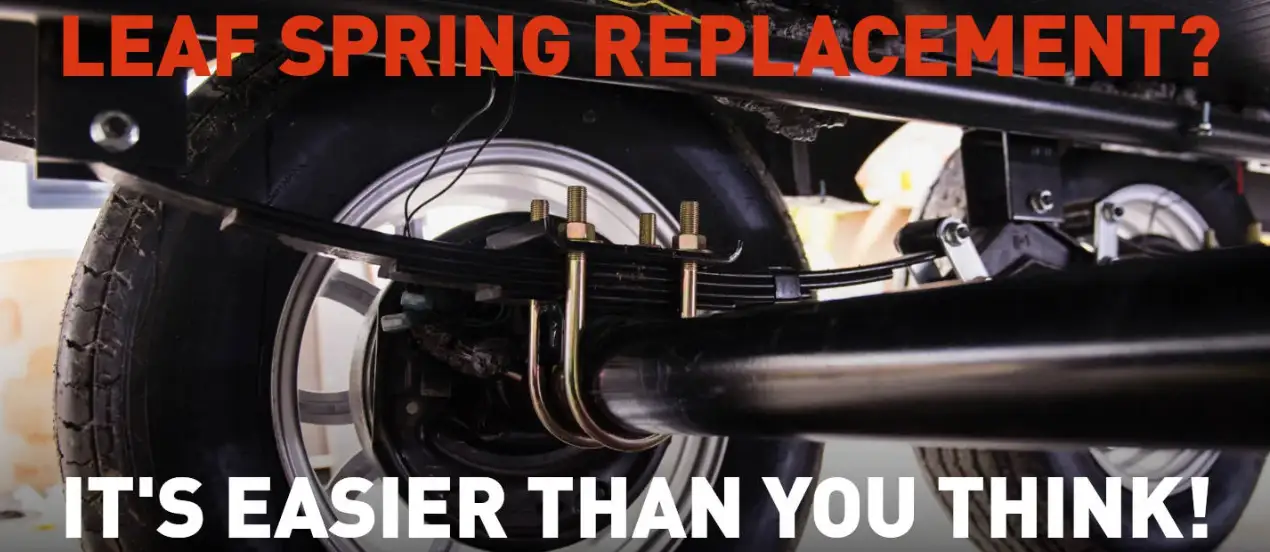

Replacing your trailer suspension or axles ? Click below to check out these step-by-step guides!

Replacement Parts of a Trailer

1. Trailer Couplers

Coupler definition: a trailer coupler attaches to the tongue of the trailer and securely latches onto the tow vehicle's hitch ball.

This connection is essential for towing and provides stability and safety. It plays a crucial role in maintaining a firm attachment between the trailer and the tow vehicle, ensuring that the hitch ball remains securely in place while the vehicle is in motion.

Most trailer couplers are made up of a cup or receiver component to accept the hitch ball, a body component that attaches to the trailer as well as a latching mechanism to secure the coupler onto the ball.

What is a channel-mount coupler?

Channel-style couplers allow you to easily raise or lower the height of the coupler, providing an adjustable solution for trailers that differ in height from their tow vehicle.

The coupler's body can be conveniently moved within a channel to different heights and this adds a layer of flexibility, however, it also requires careful adjustment to ensure a safe, secure fit.

Channel couplers are often used by towers that use multiple tow vehicles. This is because it makes it easy to level trailers of differing sizes and payloads easily on the go.

Trailer latches are typically sold with the trailer coupler. To see trailer couplers, shop CURT couplers.

2. Trailer Latches

Latch definition: latches lock the trailer hitch ball into the trailer coupler. They complete the function of the trailer coupler by preventing the trailer ball from leaving the trailer coupler and are essential for safety.

Latch designs vary in both form and functionality and there are many different types. Posi-lock and easy-lock latches are most common and are compatible with many trailer types. No-latch systems, such as CURT QuickPin™ couplers, are designed for ease and convenience, allow for swift coupling and decoupling using just a hitch pin.

Trailer latches are typically sold with the trailer coupler. To see trailer couplers, shop CURT couplers.

What is a latch-free coupler?

CURT QuickPin™ couplers simplify coupling and give you confidence by reducing the chances of an improper latch. The latch-free design features a single pin to secure the tongue onto the ball.

These no-latch trailer couplers have no moving, mechanical parts and are available in multiple sizes and fit most existing trailer bolt hole patterns.

3. Trailer Jacks

Trailer jack definition: A trailer jack is a mechanical device that is used to raise and lower the trailer, facilitating hitching and unhitching to a tow vehicle.

A trailer jack is typically mounted on the trailer's tongue and can be operated manually or electrically.

There are several types of trailer jacks, which range from simple swivel jacks and marine jacks, to A-frame jacks an direct-weld square jacks.

What is an electric trailer jack?

An electric trailer jack can transform your hitching experience. Standard trailer jacks are operated manually and hold up the trailer which can have an immense amount of weight.

This means hand-cranking a trailer jack can be quite cumbersome — the handle may need to be fully turned dozens of times to fully raise or lower your trailer.

The electric trailer jack peforms this task for you and makes lowering and hitching your trailer a breeze. Simply push the raise or lower button and the electric jack will take care of the rest, ensuring your towing experience is simple and smooth.

Trailer Jack Replacement Parts

CURT offers a full line-up of trailer jack replacement parts and accessories that vary from replacement hand cranks, wheels, swivels, bearings, food-pads, lift nuts, gears and more.

These parts and pieces are vital for a smoothly functioning trailer jack. Replacing your CURT trailer jack is always an option, however, using OEM CURT trailer jack replacement parts can help to replace worn out parts and prevent the need to replace the entire jack itself.

Trailer jacks hold up large amounts of weight and require an professional installation — without this your trailer may be unsafe. You can take it into an automotive shop to have the jack installed professionally to prevent issues.

4. Trailer Wheel Chocks

Wheel chocks are mobile devices that are placed on each side of the trailer wheel when parked and not in use. Wheel chocks are important for safety to have on hand anytime you are towing or traveling with a trailer. This is because once the trailer is parked and unhitched from the vehicle, there is nothing to stop the trailer from rolling.

This is where wheel chocks play an important role — the secure the trailer, prevent it from moving and this stops the trailer from becoming mobile and crashing into another vehicle or person.

Wheel chocks also help to protect your belongings inside the trailer by preventing movement and shifting.

What is are CURT HD wheel chocks?

CURT HD wheel chocks take trailer safety to the next level.

Similar to regular wheel chocks, these special, heavy-duty wheel chocks are placed on each side of the trailer tire. However, this is where regular wheel chocks are limited and the HD wheel chocks outshine.

The HD wheel chocks are made from heavy rubber compound which means they will not slip or slide when weight is placed on them from the trailer. LIkewise, the rubber material provides exceptional traction during wet, slippery or inclement weather.

Furthermore, the HD wheel chocks mount to your trailer frame, preventing the need to carry your wheel chocks inside your trailer or vehicle.

Learn more about CURT HD wheel chocks.

5. Wheel Bearing Protectors

Definition: a trailer wheel bearing protector covers the wheel hub. Wheel bearing protectors act like a shield for your wheel bearings and serve two crucial roles. They guard the wheel bearings against water, dirt and road debris and supply a continuous grease supply for smooth wheel rotation.

Neglected, dirty or wet wheel bearings can cause noise, vibration and reduce economy while overheating and escalating from a minor nuisance to a major issue rapidly.

CURT's wheel bearing protectors ensure silent and efficient wheel movement and prevent bearing breakdown, which can lead to an accident.

Stress-free, No-latch Coupling

If you've ever coupled a trailer, you know how stubborn a coupler latch can be.

That's why QuickPin™ does away with the traditional latch design. In fact, it doesn't have a latch at all! Hook up your trailer with a simple, single pin, and leave the stress behind.

6. Trailer Safety Chains

A safety chain is a length of chain strong enough to keep the trailer from completely separating from the vehicle if it ever becomes disconnected while towing. Two safety chains should be used on every towing setup.

Safety chains are fixed to the trailer tongue and have hooks that allow them to be linked to a vehicle's trailer hitch.

7. Trailer Wiring Harnesses

A trailer wiring harness is a length of wire at the back of a vehicle that allows its electrical system to connect to a trailer. Integrated with the vehicle's existing wiring, it provides a standard connector, such as a 4-way flat plug.

A trailer wiring harness is one of the most vital towing parts but can often be overlooked. It supplies power to the trailer lights and synchronizes them with the vehicle's taillights. It can also be used to connect trailer brakes and auxiliary power.

8. Trailer Winches & Winch Straps

Definition: a trailer winch is a device that is mounted at the front of the trailer and is used to hoist heavy equipment, boats, UTVs or vehicles onto the trailer. A trailer winch is a hand-cranked device that pulls the winch strap towards the trailer coupler.

Trailer winches are common on boat and utility trailers. They are used to pull the boat up and onto the trailer while also working to keep the boat secure.

Trailer winches can also be used on utility trailers for securing equipment, pulling gear onto the trailer or even securing the gate of the trailer itself.

Before purchasing a winch be sure to choose the right size winch for the trailer and cargo you intend to tow.

9. Trailer Axle Parts

Trailer axle parts vary from brake assemblies and suspension parts to axle bearings, dust covers, wheel hubs, shock assemblies, leaf springs and hardware.

Protect your vehicle with robust trailer axle components built to endure the challenges of outdoor adventures in your RV.

CURTs extensive collection of RV suspension enhancements features sought-after systems such as Equa-Flex and Road Armor, alongside air suspension alternatives.

We provide essential trailer axle replacement parts, including trailer shocks, axle hanger brackets, and other crucial installation or repair hardware.

Why are replacement trailer axle parts important?

Trailer axle parts parts wear when traveling in your RV and are important to replace to prevent further issues down the road.

Replacing your worn trailer axle parts prevents your RV from deteriorating and degrading and maintaining your RV ensures that all parts and systems are working as they are intended.

RVs that have proper maintenance will uphold their value while staying safe and dependable.

Step-by-Step Trailer Part Replacement Guides

1: Trailer Jack Replacement

Step 1: Elevate the Trailer Frame

Begin by ensuring your trailer is on flat ground and the wheels are blocked. Use a floor jack (not the tongue jack) to elevate the trailer frame and stabilize it with appropriate jack stands under the frame.

Step 2: Detach the Jack Foot or Wheel

If your jack includes a foot or wheel at the base, remove this before taking off the entire jack assembly. These parts are typically secured with a basic safety or cotter pin with a clip. Detach this and keep it aside.

Step 3: Unfasten the Bolts or Cut the Welds

Jacks are usually attached to the trailer with standard nuts and bolts. On A-frame jacks, bolts are inserted through the mounting bracket vertically, while on swivel-style jacks, the hardware might be horizontal. Lightweight jacks might use U-bolts.

For welded jacks, cut the welds using an angle grinder or a similar tool. If uncertain, seek professional assistance.

After removing the hardware or welds, take off the old jack and put it aside.

Step 4: Prep the Mounting Area

Trailers often accumulate dirt due to exposure to the elements and the road. Clean the area where the new jack will be mounted. For light dust, a simple wipe with a cloth suffices. For surface rust, consider a more thorough cleaning with abrasives or touch-up paint.

Avoid painting any areas designated for welding.

Step 5: Install the New Jack

Place the new jack on the trailer frame and secure it with the right hardware. Ensure all hardware is correctly torqued, starting with hand-tightening before achieving final torque specifications.

For jacks requiring welding, professional installation is advised.

Step 6: Reattach the Jack Foot or Wheel

Put back the foot or wheel on your new jack's bottom. Note that some jacks may not accommodate these accessories, while others might include them.

Step 7: Test the Installed Jack

Once the jack is firmly fixed, use your floor jack to lift the trailer frame again and remove the jack stands. This returns the trailer to its regular position. Before towing or hitching, test the new jack by repeatedly raising and lowering it to ensure proper function.

To learn more about how to buy, install, operate and maintain your trailer jack, see our blog post.

2: Trailer Hub Replacement

Step 1: Remove the Wheel:

Jack up the trailer using a floor jack under the frame.

Secure the trailer with chocks and lift until the tire is off the ground.

Use a jack stand for extra support.

Remove lug nuts with an impact driver or ratchet and take off the wheel.

Step 2: Remove the Dust Cap:

Pry off the dust cap from the hub with a flathead screwdriver.

Step 3: Remove the Spindle Nut:

Remove the cotter pin from the castle nut in the hub center with pliers.

Unscrew the spindle nut using an impact driver.

Step 4: Remove the Hub:

Take off the washer, then slide the hub off the spindle.

Catch any loose bearings.

Step 5: Inspect the Brake Assembly:

Examine brake components like shoes and springs.

Clean any grease from the magnet, shoes, and spindle.

Step 6: Install the New Hub:

Press the new hub onto the spindle.

Install the outer bearing and washer.

Finger-tighten the castle nut, then torque it.

Back off the nut and retighten by hand.

Secure with a new cotter pin.

Step 7: Replace the Dust Cap:

Tap the dust cap into place on the hub with a rubber mallet.

Step 8: Reattach the Wheel:

Put the wheel back on and finger-tighten lug nuts.

Tighten nuts with a wrench or impact driver in a star pattern.

Lower the trailer and torque the nuts.

Check lug nut torque after 10, 25, and 50 miles.

To learn more about how to install wheel hubs see our blog post.

3: Trailer Wiring Replacement

Step 1: Remove Old Wires

Carefully take out the old wiring harness from your trailer, making sure not to damage any lights or components.

Step 2: Plan Wiring Route

Before installing new wires, decide on their path. Ensure they won’t get pinched or exposed to damage and are securely tucked under the vehicle.

Step 3: Install New Wires

Lay the new wires according to your plan, protecting them in a cable sleeve to shield them from the elements and debris.

Step 4: Connect Wires to Components

Attach the new wires to lights, brakes, and other parts. Be aware of the different wire colors and their functions.

Step 5: Ground the Wiring

Properly ground the wiring to the vehicle chassis or ground wire to avoid issues with functionality or electrical shorts.

Step 6: Test the Wiring

Check all lights and electrical parts to ensure they’re working correctly. Lights should be bright and responsive.

Step 7: Secure Any Loose Wires

Use zip ties or wire loom to fasten any dangling wires. Keep them away from moving parts or hot areas, ideally hidden under the vehicle.

Step 8: Final Check

Do a thorough inspection and test run. Ensure all lights, including brake lights and turn signals, work on both the tow vehicle and trailer. Retest after a few miles to confirm everything is stable for longer trips.

For the complete step-by-step process read our Trailer Wiring & Installation Help guide.

4: Trailer Axle Replacement

Step 1: Jack Up Trailer

Use a floor jack to lift the trailer by its frame, ensuring stability with jack stands for safety.

Step 2: Remove the Wheels

Unbolt lug nuts using a tool like an impact driver and remove the wheels, setting them aside.

Step 3: Cut Wires (If Applicable):

For electric brake axles, cut the power and ground wires to avoid damage during axle removal.

Step 4: Lift Axle

Elevate the axle with the floor jack, placing jack stands underneath for support.

Step 5: Remove the Shackles

Detach shackles from the leaf springs, checking for wear and tear.

Step 6: Remove Hanger Bolts

Unfasten the bolts that secure leaf springs to the hangers, inspecting for necessary replacements.

Step 7: Lower Axle

Carefully lower and remove the old axle from under the trailer.

Step 8: Install New Axle

Position the new axle under the trailer, aligning it correctly before lifting into place.

Step 9: Attach Leaf Springs

Reattach leaf springs using bolts, ensuring proper alignment and lubrication.

Step 10: Torque Bolts

Securely tighten all bolts to the manufacturer's specified torque.

Step 11: Reconnect Brake Wires

Rejoin brake power and ground wires using appropriate connectors.

Step 12: Reinstall Wheels

Place wheels back on, hand-tighten lug nuts, then use a torque wrench for final tightening.

For the in-depth, complete step-by-step process read our Complete Guide for Replacing a Trailer Axle.

CURT Towing 101 — Learn Everything You Need to Know About Towing

Looking for more?

Discover more great tips and how-tos on the Lippert blog -- your destination for all things RVing, towing, boating and beyond!

ARIES

ARIES  CURT

CURT  LUVERNE

LUVERNE  UWS

UWS